Innovation is the key to success for electronics. As the demand for smaller and more flexible, high performance electronic gadgets continues to rise, manufacturers are searching for ways to improve the process of assembly. One innovative technology that has received a lot of attention is flex circuit manufacturing.

Flex circuits are also referred to as flexible printed circuit board (PCBs) and offer many benefits over rigid PCBs. These circuits can be bent, twisted and molded to different shapes. They are great for applications requiring complex designs, a limited amount of space or greater durability.

Flex circuits enable manufacturers to challenge the limits of design by offering an adaptable base that adjusts to the form of the product. This flexibility lets designers create more innovative and compact designs, ultimately creating lighter and smaller devices. Imagine a smartphone that seamlessly is curved around the hand. Wearable health tracker that can be worn discreetly around your wrist. Perhaps even a smart device that has a seamless, ergonomic design. Flexible circuits allow engineers and designers to turn these concepts into reality, unlocking a new world of possibilities for product development.

Flexible circuits are long-lasting and provide more aesthetic benefits. Traditional PCBs can suffer destruction from shock, vibration, and repeated bends. Flex circuits are made with substances that are resistant to these elements, making them extremely robust. This makes them ideal for industries such as automotive and aerospace, as well as medical, that need electronic components that can withstand the most extreme environments.

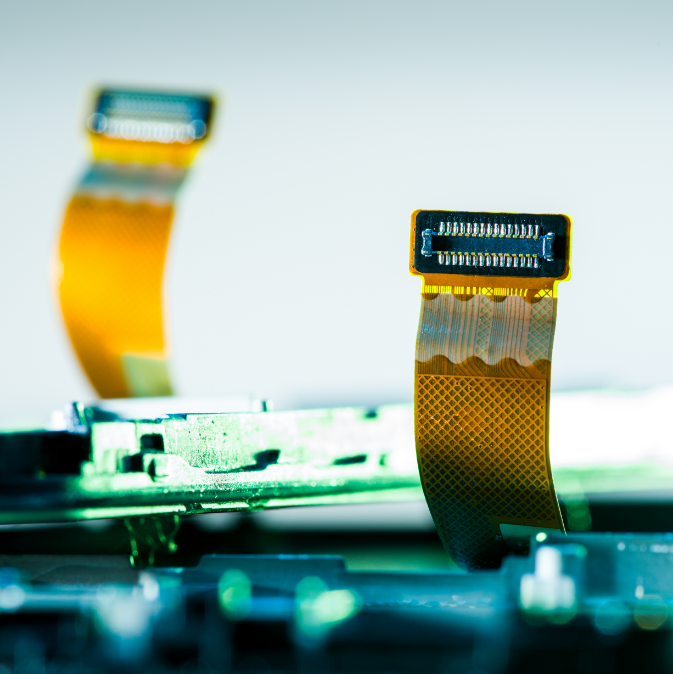

The manufacturing methods employed in the production of flex circuits contribute to their dazzling capabilities. Flex circuits, unlike rigid PCBs, are made by a flexible surface such as polyester or polyimide. The substrate is the basis of the circuit and allows it to be bent and bent while still maintaining electrical connectivity. Flexible circuit makers employ advanced manufacturing techniques to precisely cut circuits, include complex interconnects, or place components directly onto the flexible substrate.

The integration of components directly to the flex circuit known as surface mount technology (SMT) also increases the functionality and flexibility of these circuits. SMT lets manufacturers place electronic components directly on flex circuits. Connectors that are bulky are eliminated and the overall device size is reduced. This streamlined approach not only reduces space, but also enhances the integrity of signals, decreases weight and improves thermal management.

Flex circuit manufacturing allows for rapid prototyping and the ability to scale production. Flexible circuit designs allow rapid iterations in the prototyping stage, which accelerates the development process of a product. Additionally, as they can be made in large quantities by automated manufacturing processes, they are affordable solutions for large-scale production. Flex circuits are a great choice for companies looking to quickly bring innovative ideas to the market. For more information, click flex circuit manufacturer

The availability of reliable flex-circuit manufacturers is increasingly crucial since the need for electronic devices that can be flexed to grow. Partnering with reputable and experienced manufacturers is crucial for ensuring the quality as well as the precision and consistency of the production of flex circuits. They have the experience and expertise to help you through the process of designing, provide valuable insight into material selection and ensure compliance with industry standard.

In the end, flex circuits are essential components that enable electronic systems to be built today to achieve the most advanced degree of complexity. They are at the core of many complex systems, from displays in consumer products to military-related applications. Flexible substrates, which are able to move through small spaces effortlessly, allow engineers to design complex designs and still fit into the assembly footprint. Although there are various ways to run circuits, they can’t be compared to the mechanical or electrical properties of flex assembly when meeting strict size requirements. Flexible circuits are by far the best option for projects that require complex interconnections, combining multiple technology into a well-designed package.